PLC & HMI software preparation

PLC (Programmable Logic Controller) is a type of industrial computer system that is used to control and automate machinery and processes in manufacturing plants, factories, and other industrial settings. PLC software is used to create programs that instruct the PLC on how to control specific equipment and processes. HMI (Human Machine Interface) software is used to create user interfaces that allow operators to interact with the PLC system. HMI software typically provides a visual representation of the equipment and processes being controlled by the PLC, and allows operators to monitor and control various aspects of the system. A PLC and HMI software preparation service for a website would involve the creation and customization of software programs for PLCs and HMIs. This service would typically include consultation with the client to determine their specific needs and requirements, the design and development of software programs, testing and quality assurance, and ongoing support and maintenance. The website for this service would likely provide information on the various types of PLC and HMI systems supported, as well as details on the customization and integration services available. It may also provide case studies or examples of successful projects completed for other clients, and pricing information for different service packages.

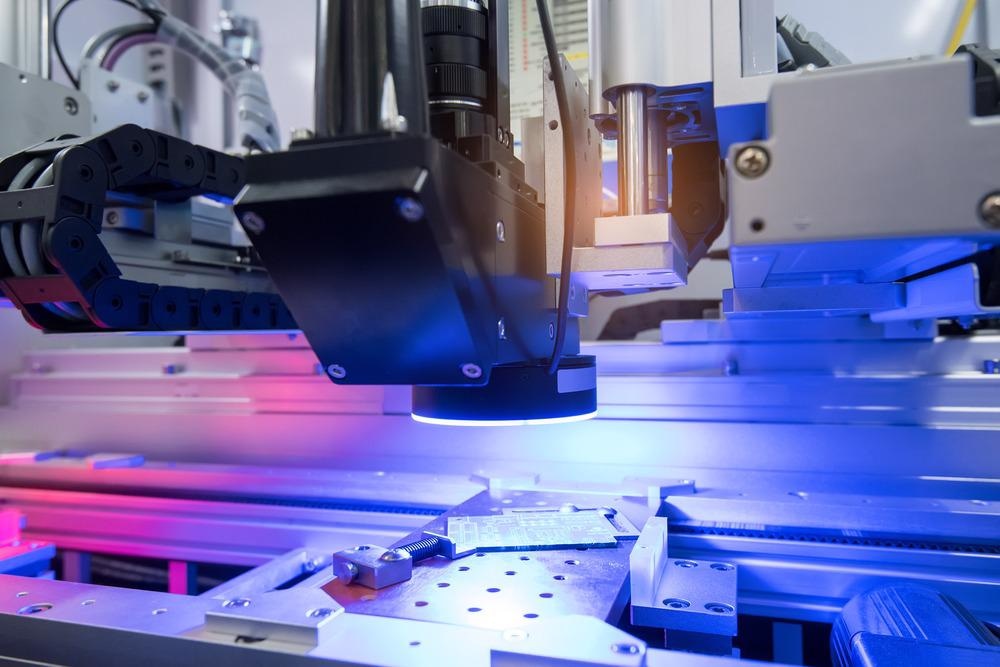

Machine inspection and start-up

Machine inspection and start-up service is an important offering for businesses that rely on machinery to carry out their operations. This service involves a trained technician visiting the client's facility to inspect and assess the functionality of their machinery, as well as perform necessary repairs, maintenance, and adjustments to ensure that the machines are operating at optimal performance. The inspection process typically involves a thorough examination of the machinery, including visual inspections, checks for proper alignment, lubrication and fluid levels, and verification of proper electrical connections. If any issues or concerns are identified during the inspection, the technician will communicate these to the client and make recommendations for repairs or upgrades. After the inspection is completed, the technician will perform start-up procedures to ensure that the machines are functioning as intended. This may involve testing the equipment with a variety of loads or materials to confirm that they are capable of handling the client's specific requirements. The ultimate goal of machine inspection and start-up service is to ensure that the client's machinery is operating at peak efficiency, reducing the risk of downtime and costly repairs, and maximizing productivity. This service may be provided on a one-time basis, or as part of an ongoing maintenance agreement to ensure the continued performance and longevity of the client's machinery. PLC (Programmable Logic Controller) is a type of industrial computer system that is used to control and automate machinery and processes in manufacturing plants, factories, and other industrial settings. PLC software is used to create programs that instruct the PLC on how to control specific equipment and processes. HMI (Human Machine Interface) software is used to create user interfaces that allow operators to interact with the PLC system. HMI software typically provides a visual representation of the equipment and processes being controlled by the PLC, and allows operators to monitor and control various aspects of the system. A PLC and HMI software preparation service for a website would involve the creation and customization of software programs for PLCs and HMIs. This service would typically include consultation with the client to determine their specific needs and requirements, the design and development of software PLC

Machine manual preparation and translation

Machine manual preparation and translation is a service that involves the creation of technical manuals or user guides for industrial machinery. These manuals provide detailed instructions on how to operate and maintain the machinery, as well as important safety guidelines and troubleshooting information. The preparation of machine manuals typically involves the collaboration of technical writers, engineers, and subject matter experts to create accurate and comprehensive documentation. The manuals may include illustrations, diagrams, and photographs to help users understand the machinery and its components. In addition to the preparation of machine manuals, this service also includes translation of the manuals into different languages, which is essential for companies that operate in global markets. Machine manual translation involves the conversion of technical content into a target language, while ensuring that technical terms and concepts are accurately translated. The machine manual preparation and translation service helps businesses to improve safety, reduce the risk of equipment damage or failure, and increase productivity by providing clear and concise instructions for the operation and maintenance of their machinery. This service is typically offered as a standalone service, or as part of a comprehensive technical documentation package.

Electrical installation and wiring

Electrical installation and wiring is a service that involves the installation of electrical systems in commercial, industrial, and residential buildings. This service includes the design, planning, and installation of wiring, lighting, electrical panels, circuit breakers, and other electrical components. The installation process begins with a consultation between the client and the electrical contractor to determine the specific needs and requirements for the project. The contractor then designs an electrical system that meets the needs of the client, taking into account factors such as electrical load, building codes, and safety regulations. Once the design is complete, the contractor proceeds with the installation of the electrical system. This includes running wires, installing electrical panels, mounting light fixtures, and connecting electrical equipment. The contractor also ensures that the electrical system is properly grounded and that all connections are secure. Electrical installation and wiring services are essential for the safe and reliable operation of a building's electrical system. Proper installation and wiring help prevent electrical failures and reduce the risk of electrical fires. This service is typically offered by licensed and certified electrical contractors who have the expertise and experience to ensure that electrical installations are completed to code and to the highest standards of quality and safety.

Electrical design and modifications

Electrical design and modifications" is a service that involves the design and modification of electrical systems in various types of buildings, including commercial, industrial, and residential structures. This service includes consultation with the client to determine their specific needs and requirements, as well as the design and implementation of electrical systems that meet local building codes and safety standards. The service provider typically begins by assessing the client's current electrical systems and identifying areas that require modifications or improvements. They then develop a customized electrical design that meets the client's specific needs and budget. This may involve selecting and installing the appropriate electrical components, such as wiring, lighting fixtures, circuit breakers, and electrical panels. The modifications to electrical systems may be necessary to accommodate changes in the building layout, changes in power requirements, or changes in the equipment being used. The service provider may also be involved in upgrading the electrical system to ensure it meets current safety and energy efficiency standards. This service is typically provided by experienced and qualified electrical engineers or technicians who have the expertise to design and implement electrical systems that are safe, reliable, and efficient. The electrical design and modifications service can help improve the functionality, efficiency, and safety of electrical systems in various types of buildings, and can ultimately help save clients money on energy costs while reducing the risk of electrical hazards.

PLC & MHI software modifications and upgrades

Modifiche su software e upgrade PLC & HMI is a service that involves making modifications to existing software programs and upgrading programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for industrial machinery. This service includes consultation with the client to determine their specific needs and requirements for the modifications and upgrades, as well as design and development of software programs, testing and quality assurance, and ongoing support and maintenance. Modifications to software programs and upgrades to PLCs and HMIs are often necessary to improve the performance, efficiency, and reliability of industrial machinery. The process begins with a consultation between the client and the service provider to determine the specific modifications and upgrades needed. The service provider then designs and develops the software programs, tests them for quality and compatibility, and installs them on the client's machinery. PLC and HMI upgrades involve replacing outdated hardware and software with newer, more advanced technologies. This can include replacing older control systems with more modern, user-friendly interfaces and upgrading hardware to improve speed and reliability. Modifications and upgrades to software and PLCs and HMIs are essential for ensuring the smooth and efficient operation of industrial machinery. These services can help improve productivity, reduce downtime, and extend the lifespan of the machinery. This service is typically offered by experienced and qualified technicians who have the expertise and knowledge to provide the highest level of service and support.